| |

|

|

|

|

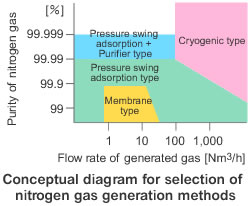

Major gas generation (separation)

technologies are described as below.

For separating nitrogen and oxygen, the major compositions

of air, the optimum method is selected according to

the application map on the right, for a required flow

rate, purity, etc., in consideration of its economical

efficiency. |

|

|

|

|

Pressure swing

adsorption type |

| |

Oxygen or nitrogen is selectively adsorbed with adsorbent. The components adsorbed

under pressure are desorbed by depressurizing. It is

called PSA (Pressure

Swing Adsorption)

because of such repeated pressurizing and depressurizing.

In generating nitrogen gas, high purity nitrogen gas

(about 99 - 99.99%) (containing argon) is separated, using

the difference in adsorption speed between nitrogen

and oxygen.

In addition, higher purity nitrogen (99.999%) can be

achieved in combination with Purifier.

The capacity ranges from 1 NL/min to several 1000 Nm3/h.

Some small-scale equipment is shipped as assembled in

a cabinet, while some large-scale plant is assembled

on the site.

|

|

|

Membrane method |

| |

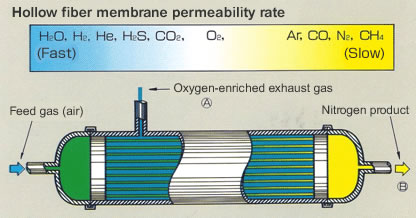

It

uses the filtration effect by hollow fiber membranes.

High purity nitrogen gas (about 95 - 99.9%) is separated,

using the difference in membrane permeability characteristic

between nitrogen and oxygen when delivering high-pressure

air to a membrane module. Among various types of generators,

it is used in where relatively low purity nitrogen is

required comparing with other methods. Once compressed

air enters a hollow fiber membrane, moisture, oxygen,

and CO2, which are permeable through membranes,

passes through the membrane, while nitrogen and argon,

which are not permeable through membranes, are separated

as a product. It

uses the filtration effect by hollow fiber membranes.

High purity nitrogen gas (about 95 - 99.9%) is separated,

using the difference in membrane permeability characteristic

between nitrogen and oxygen when delivering high-pressure

air to a membrane module. Among various types of generators,

it is used in where relatively low purity nitrogen is

required comparing with other methods. Once compressed

air enters a hollow fiber membrane, moisture, oxygen,

and CO2, which are permeable through membranes,

passes through the membrane, while nitrogen and argon,

which are not permeable through membranes, are separated

as a product.

The

selectivity of gases is enhanced when the pressure and

temperature of feed air are high. The

selectivity of gases is enhanced when the pressure and

temperature of feed air are high.

It is generally shipped as a unit packaged in a cabinet,

which contains a required number of modules (photo on

the above), a bundle of hollow fiber membranes (photo

on the left), according to the required purity and flow

rate of the generated gas. |

|

|

Cryogenic type |

| |

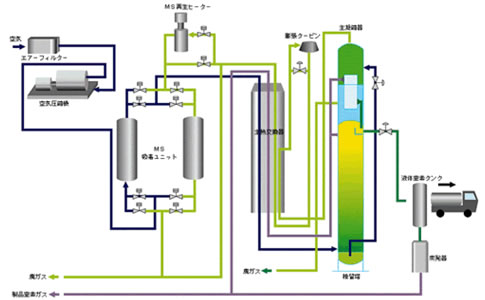

High

purity gases (more than 99.999%) are extracted using

the difference in boiling point (b.p.) among nitrogen

(b.p.=-195.8oC), oxygen

(b.p.=-183oC), and

argon (b.p.=-185.7oC),

in the liquefied air. It is suitable where

a large amount of high purity nitrogen is required. High

purity gases (more than 99.999%) are extracted using

the difference in boiling point (b.p.) among nitrogen

(b.p.=-195.8oC), oxygen

(b.p.=-183oC), and

argon (b.p.=-185.7oC),

in the liquefied air. It is suitable where

a large amount of high purity nitrogen is required.

A small-scale 150 Nm3/h equipment requires

a space of 10 x 20 m. Kobe steel, Ltd. has been involved

in manufacture of this equipment since 1930s, and has

abundant experience both in and outside Japan.

|

|

|

|

|

|

|

The information contained in this

website is subject to change and/or delete without prior notice.

We shall not be held liable for any direct or indirect damages caused

from use of this website.

It is the responsibility for users to check against the latest version

of other references before using any legal standards or other figures.

all rights reserved, Copyright © Shinko AirTech, Ltd.

|

|